What is DAICARAT?

A

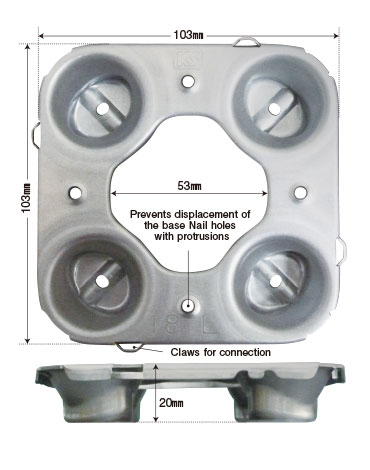

The under-floor of a wooden house has advanced so far with Daikarat. Instead of installing ventilation openings in the rising part of the foundation, a spacer is inserted between the foundation and the earth. This "Daikarat" is an innovative foundation packing that uses an unconventional material, a one-piece pressed structure of 1mm-thick special steel. By simply using this material, the lifespan of a wooden house can be dramatically extended, and a house with less moisture under the floor makes its inhabitants healthier as well.

B

Durability incomparable to resin, rubber, and wood

Made of a special steel plate plated with water and salt resistance. It does not change over time like resin or rubber. It is a reliable material that lasts longer than a wooden house itself.

C

Airflow through the entire area under the floor

Because it is supported by four column legs, air can pass through the area where the packing is placed. This keeps the subfloor dry and prevents corrosion and termite damage.

Moisture dries out as it vents through the Daikarat itself, which prevents condensation.

The packing method is also highly evaluated for not transmitting moisture from the concrete foundation to the foundation, but this is a problem if the packing itself is prone to condensation.

However, if the packing itself is prone to condensation, it is a problem.

D

Absorption of impact

In the event of a strong force, such as a direct earthquake, the integrally pressed body will slightly deform to absorb the large force and protect the foundation, base, and columns.

-

Daikarat under-floor ventilation hardware for wooden construction

-

If "Daikarat" is laid on the concrete foundation and the foundation is placed, the wind will pass through the entire area under the floor.

-

Example of "Daikarat" construction